August 15, 2018

Introducing BEGA Wooden Poles

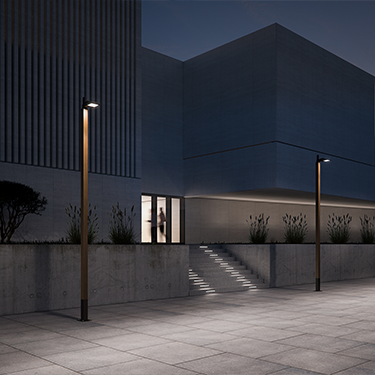

Soften the built environment

BEGA has always strived to create products which are a seamless blend of tradition and innovation. Our products - from the forms to the materials used - are intended to be architecturally neutral and timeless. The introduction of BEGA wooden poles provides architectural designers and urban planners with an opportunity to soften the built environment using natural materials of the highest quality. Pair BEGA pole top luminaires with a wide variety of wooden pole styles and finishes for the perfect combination of form and function.

Round or square, tapered or straight - BEGA’s wooden poles are perfectly suited for every project thanks to their quality of design and beautiful craftsmanship. Round styles are available in four heights, square styles are available in three heights.

Materials

With over 60,000 species of trees on Earth, wood has been a trusted construction material in nearly all regions of the world for centuries. Each species has their own unique strengths, but the Scots Pine trees of Northern Europe are especially well suited for structural applications due to their slow, straight and sturdy growth.

BEGA’s wooden poles are crafted exclusively from Scots Pine trees forested between 80 and 100 years of growth. This timespan yields a minimum diameter of 250mm to ensure the required strength and volume for structural use.

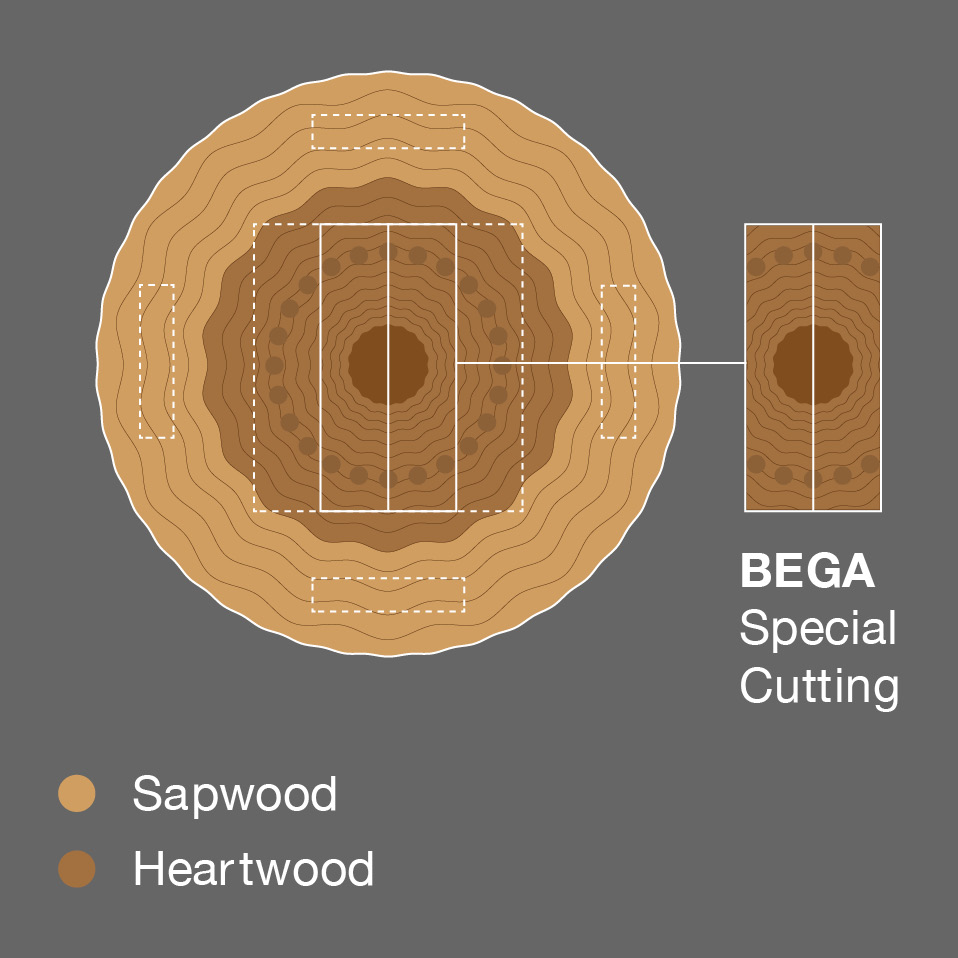

Sapwood, the outer part of a tree, is occasionally susceptible to the elements and natural risks such as termites. On the other hand, heartwood, the innermost part of a tree, is extremely durable and not affected by these threats, making it ideal for exterior applications. There are four standard dimension cuts of heartwood taken from each tree. For the construction of BEGA wooden poles, we elect to only work with the two center cuts which are of the highest quality.

While the other cuttings are used for other industries, BEGA’s careful selection of wood cuttings results in a maximum of 10% sapwood every time. As a direct result of our intentional material selection, no additional chemical treatments are needed to protect the wood.

Process

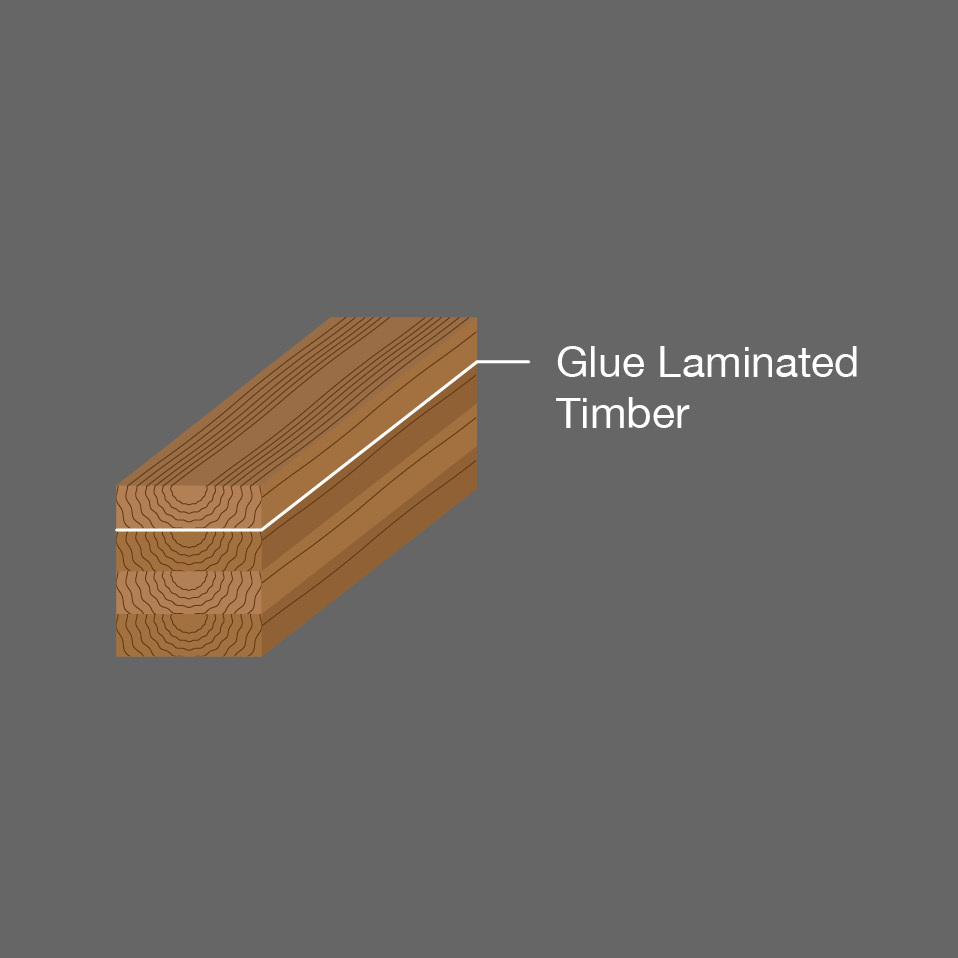

After choosing the best material for the job, these Scots Pine heartwood planks must be assembled following a precise glue lamination process. Based on decades of experience, the humidity, temperature, and drying time during assembly is carefully controlled. The specific glue used for lamination was chosen for its high resistance to UV light and high temperatures, making it ideal for exterior applications.

The perfect combination of these variables ensures strength in the lamination process, and longevity of the glue laminated timber.

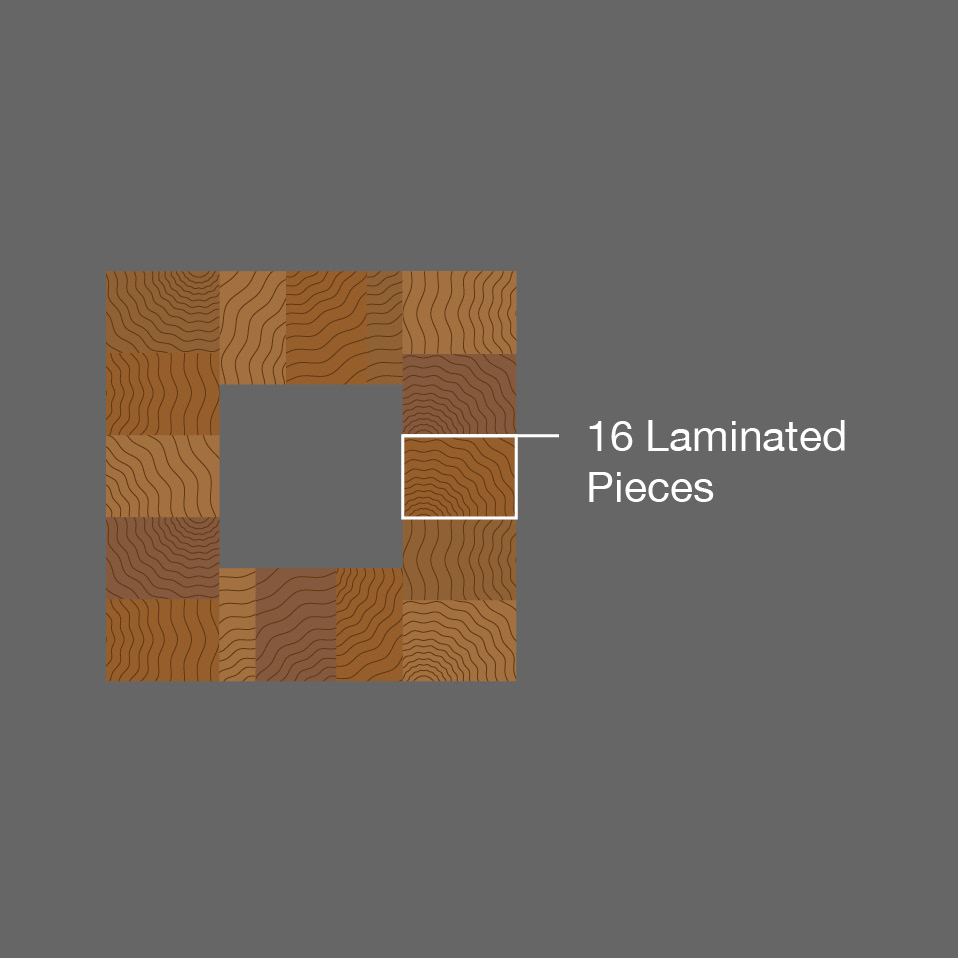

When working with wood, one of the most crucial aspects of product design is to allow the material to breathe. Unlike any other structural material, wood is living and must be able to breathe through exposed surface areas in order to adapt to all of the extreme conditions that nature presents.

A combination of glue laminated sections are assembled into a complete wooden pole with a hollow core. Each of these planks are carefully placed so that they are able to breathe on at least two sides. A minimum of 16 laminated pieces are used for each wooden pole, adding strength in the redundancy of lamination joints.

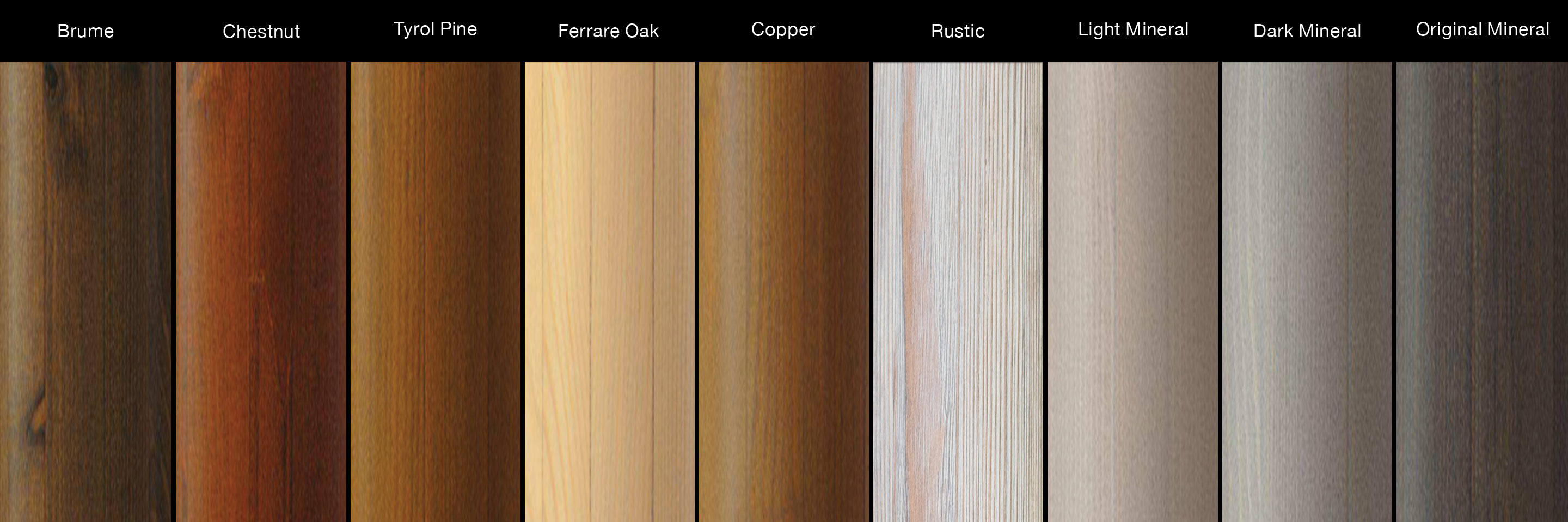

The complete glue laminated timber pole is finished with three coats of water based wood stain, available in nine unique colors. These stains provide a variety of options for designers, allowing them to coordinate the wood finish with any architectural, industrial or rural space.

Quality

Will wood hold up against the strong forces of nature and withstand the test of time? When presented with this question we need to look no further than the countless examples of wood construction throughout history. Wood has been a trusted resource for centuries, used in the construction of buildings, ships, and bridges around the world, many of which are still in service today.

Whether installed near the ocean, desert, or mountains, the durability of wooden poles is not a concern. Due to the natural properties of the material, wood is not affected by temperature, humidity, or salt. In fact, 60% of BEGA wooden pole installations are in seafront locations because wood does not rust. There are no limitations to acceptable climates for wooden poles which is proven with installations ranging from +120° F and 90% humidity, to -20° F and feet of snow.

Tropical Zone

Arid Zone

Extreme Cold

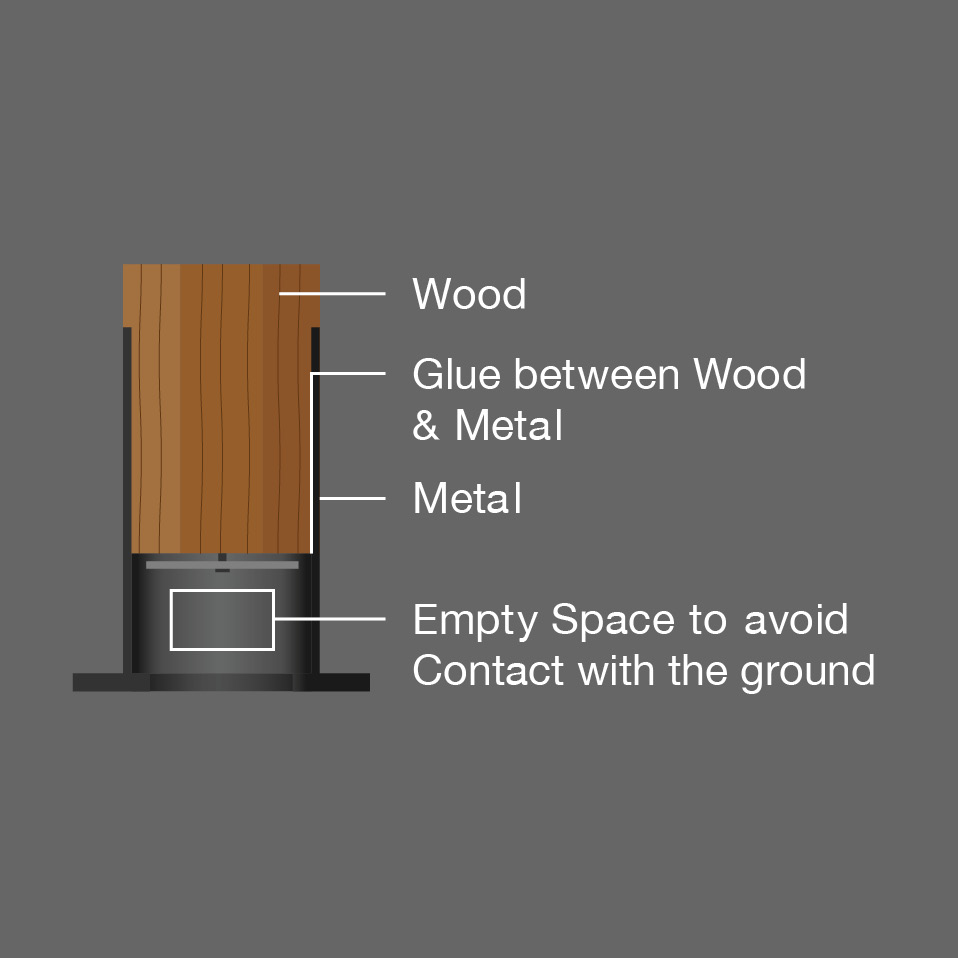

Even though the material selection and construction process make these glue laminated timber poles resistant to most risks, fumigation and anti-termite treatments are also applied due to United States regulations for all wooden poles. Furthermore, the base of the pole should avoid constant contact with the ground.

Steel bases are used to anchor the pole to the ground, providing an additional source of ventilation for the wood and avoiding surface to surface contact with the soil below. The wood is both screwed into place from below and glued to the metal base for guaranteed stability.

As the only CE certified glue laminated timber lighting pole, this marking represents the quality and strength with which these products are made. In order to demonstrate our conformance to these standards, we put our calculations to the test daily to prove that we are exceeding expectations.

Through careful material selection, product design, and manufacturing processes, BEGA wooden poles maintain an expected service life of 25 years.

1978

2010

Maintenance

Like anything left outside and exposed to the elements for years on end, the appearance of these wooden poles will gradually shift over time. In order to uphold the beautiful finish of the wood when installed, these products require some simple maintenance for primarily aesthetic purposes unless noticeable damage is seen. Restorative maintenance would then be required to ensure the life expectancy and longevity of the product. Maintenance processes are able to be performed quickly on site while the product remains installed.

Once every five to seven years an additional coat of wood stain should be applied for preventative care of products located in moderate climates. Restorative maintenance for a more thorough refinishing may also be performed in these applications every 15 to 20 years. For more extreme environmental conditions, such as seafront installations where sand and salt are aggressive, care may be required more frequently in order to maintain the original appearance. Please see BEGA Care & Maintenance Guide for more information.