Product evolution

In-grade luminaires are subjected to some of the most intense environmental conditions day in and day out. The products are not only expected to maintain their appearance over time, but also operate at peak performance regardless of weather conditions, usage, or installation method. In pursuit of continuous improvement and setting the standard of quality, BEGA saw an opportunity for improvement and ran with it.

Stainless steel has most often been our material of choice for in-grade luminaires due to its durability in highly corrosive environments. While corrosion protection is crucial, the thermal properties of stainless steel limit maximum light output compared to aluminum due to thermal management constraints for the electronics. BEGA Tricoat®, a 3-layer coating technology for corrosion protection, was developed to enable the use of aluminum in highly corrosive environments.

Three main benefits resulted from the fundamental design change to our latest in-grade luminaire families

Material

Improved thermal management by switching from stainless steel to aluminum which reveals its benefit in the form of increased lumen output capabilities.

Mechanical

Improved static load rating with newly designed housings which reveals its benefit in the form of a 2.5X increase to load capacity.

Longevity

BEGA Tricoat® reveals its benefit in the form of the highest quality material solution for one of the most extreme environments architectural luminaires are exposed to.

BEGA Tricoat®

As the name suggests, BEGA Tricoat® provides three layers of defense between an alloy and the surrounding elements. First, die-cast aluminum parts are pretreated for increased corrosion resistance. The properties of the treated surface make it nearly as hard as a sapphire. This process prevents the surface from being scratched by abrasive contact from rocks or other materials. Second, these parts are coated with a primer to seal and further protect the metal against corrosion. Lastly, the parts are coated with a powder coat paint as a final barrier between the aluminum alloy and the environment.

BEGA Tricoat® enables us to fully capture the benefits of die-cast aluminum without sacrificing our trusted durability.

Three layers of defense

Pretreatment

Die-cast aluminum parts are pretreated for increased corrosion resistance.

Primer

These parts are primed to seal and provide further protection.

Powder Coat

A powder coat acts as a final barrier between the aluminum alloy and the environment.

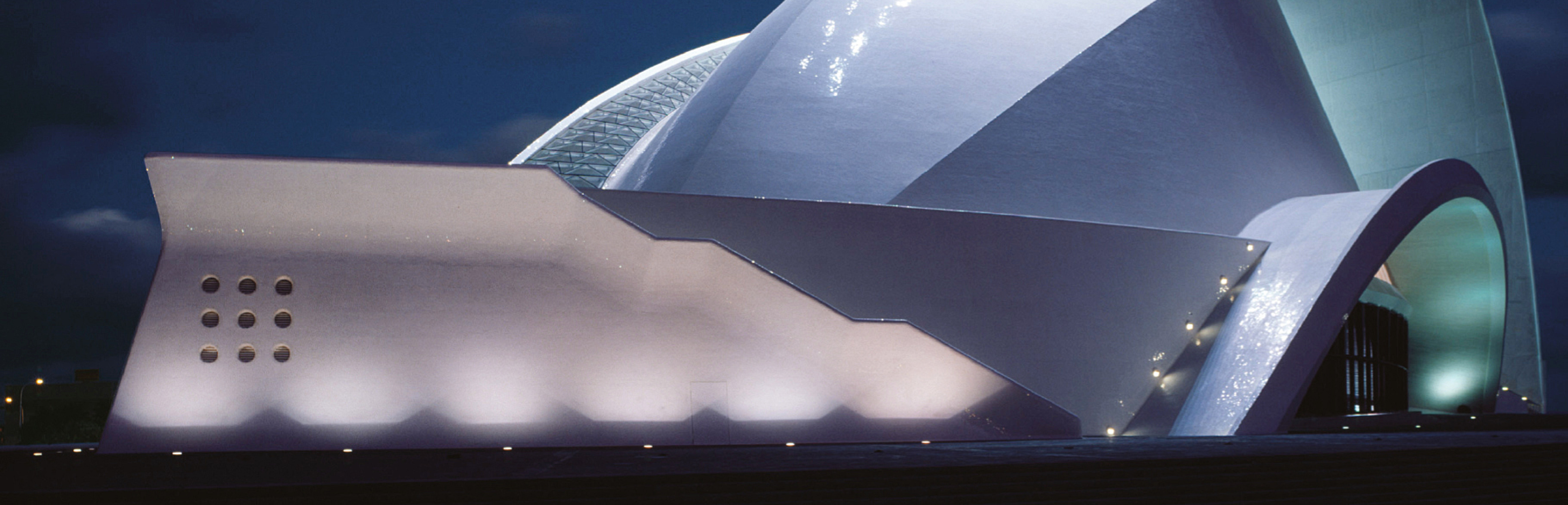

Explore New In-grade Families

In-grade luminaires are available in three segments including round, square, and pathway grazers. These luminaires maintain their appearance over time, while operating at peak performance regardless of weather conditions, usage, or installation method.

Round

A new family of round in-grades with increased lumen output, 11,000 lb. static load rating and more distribution options.

Square

BEGA Vortex Optics®, designed to manage visual comfort while maximizing efficacy, are now available in square in-grades. This family includes increase lumen output, 11,000 lb. static load rating and distributions not previously available in this form factor.

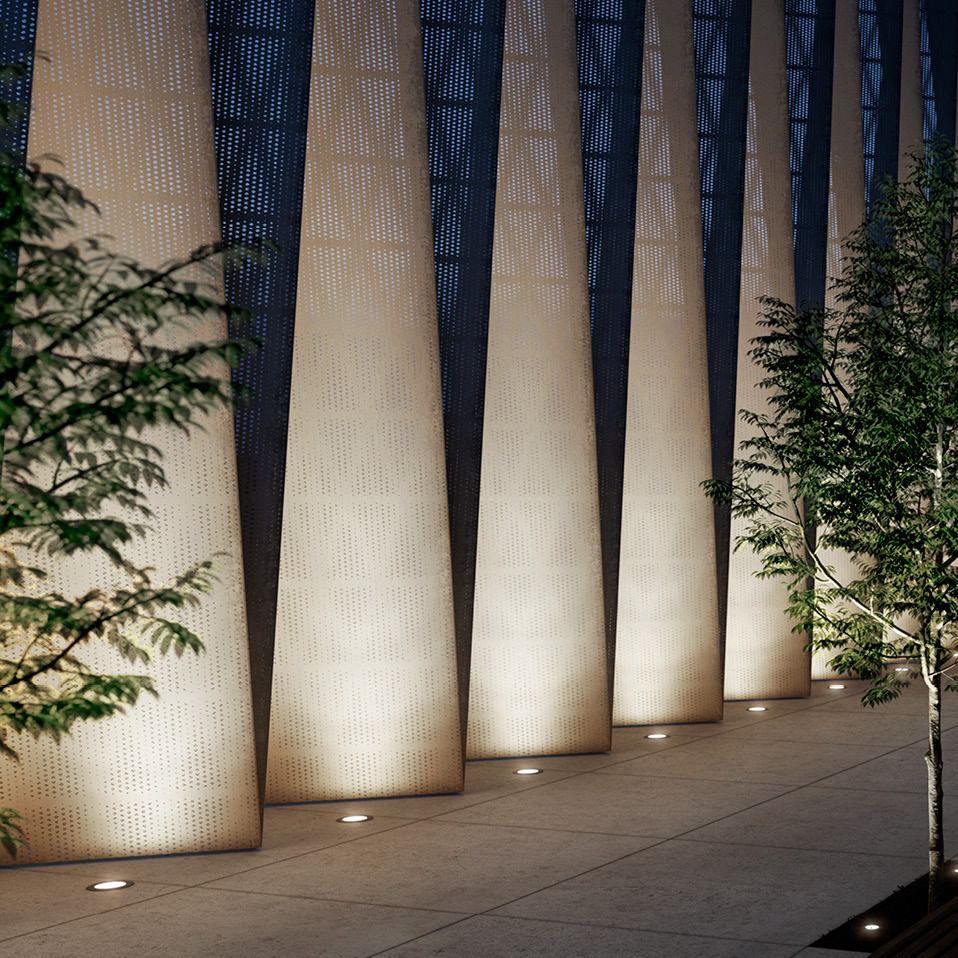

Pathway Grazer

A new family of pathway grazer in-grades with significantly increased output and an interesting new distribution to be used as a marker light or to create visual interest.